If you're in the market for a durable, low-maintenance, and corrosion-resistant flooring solution for your facility, FRP grating may be exactly what you need. As a leading FRP (Fiber Reinforced Plastic) grating manufacturer, we often get asked: "What is FRP grating, and why is it ideal for industrial flooring?" This blog answers that question and highlights the advantages that make FRP grating a top choice for demanding environments.

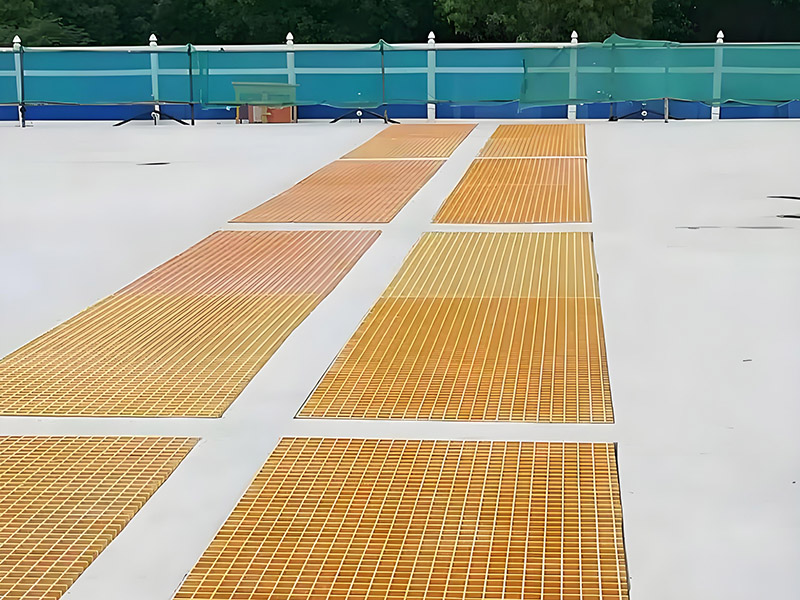

FRP grating, also known as fiberglass grating, is a grid-like flooring panel made from fiberglass reinforced with thermosetting resin. It comes in two main types: molded FRP grating and pultruded FRP grating. Molded grating is formed in a single piece for multidirectional strength, while pultruded grating uses parallel bars for higher load capacity in one direction.

FRP grating is known for its strength-to-weight ratio, chemical and corrosion resistance, and non-conductive properties, making it a popular alternative to traditional steel or aluminum grating.

FRP grating offers multiple benefits that make it ideal for industrial flooring applications:

Corrosion Resistance

FRP grating does not rust or degrade in harsh chemical or marine environments, making it superior to metal grating in facilities like chemical plants, water treatment facilities, and coastal areas.

Slip Resistance

The textured, gritted surface of fiberglass grating provides outstanding slip resistance, reducing the risk of workplace accidents, especially in wet or oily areas.

Non-Conductive and Fire Retardant

FRP is electrically non-conductive, ideal for areas with electrical equipment. Many grating types are also flame retardant and compliant with safety codes.

Lightweight and Easy Installation

Compared to steel, FRP is much lighter, which simplifies handling, reduces shipping costs, and speeds up installation time.

Low Maintenance and Long Service Life

FRP grating requires minimal maintenance, is resistant to rot, rust, and chemicals, and can last 20+ years even in tough environments.

Customizable and Versatile

Available in various panel sizes, colors, thicknesses, and resin formulations, FRP grating can be tailored to specific structural and design needs.

FRP grating is widely used in:

Chemical processing plants

Wastewater treatment facilities

Marine and offshore structures

Oil and gas refineries

Power generation stations

Pulp and paper mills

Food and beverage processing plants

Industrial walkways, catwalks, trenches, and platforms

These industries benefit from the strength, corrosion resistance, and safety of FRP industrial flooring solutions.

As a trusted FRP grating manufacturer and supplier, we provide:

Premium molded and pultruded FRP grating

Custom fabrication and sizing

Expert engineering and layout assistance

Competitive pricing and fast delivery

Our team helps customers across industries find the right industrial FRP flooring solution for their specific project needs.

FRP grating is a smart, long-term solution for industrial flooring. Its corrosion resistance, safety features, and low maintenance make it ideal for demanding environments where metal or wood grating may fail. Whether you need walkways, platforms, or trench covers, fiberglass grating delivers unmatched value and performance.

Contact us today for expert advice, pricing, and customized solutions from a leading FRP grating supplier.