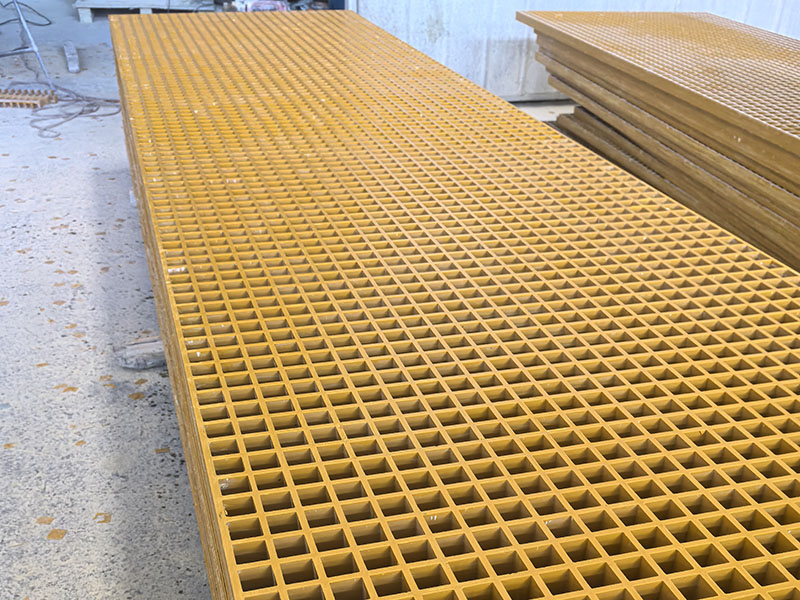

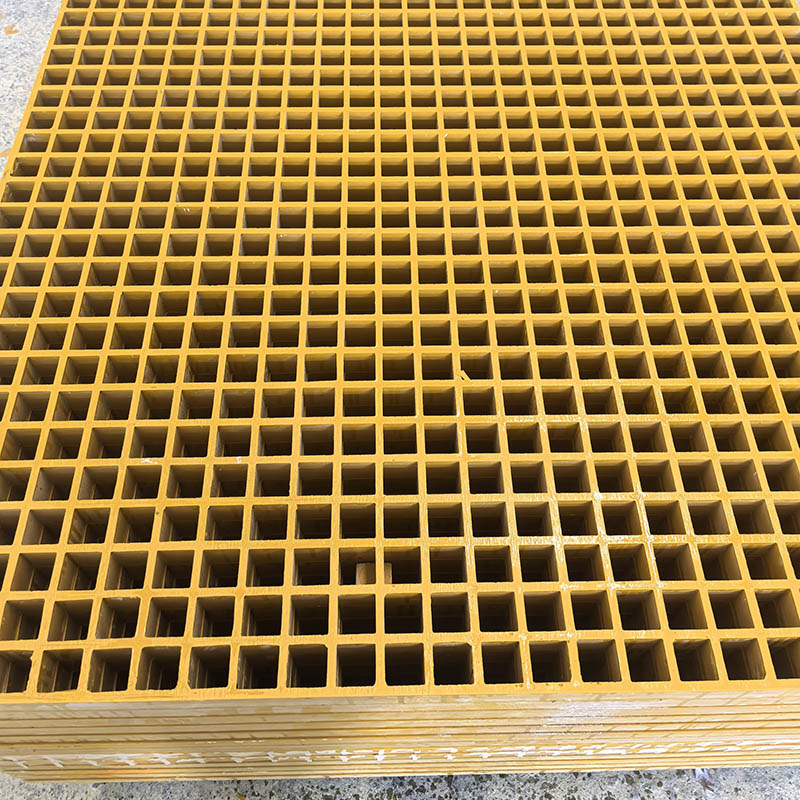

If you’re considering using FRP (Fiber Reinforced Plastic) grating for your facility, you’re likely aware of its benefits: corrosion resistance, slip resistance, non-conductivity, and lightweight strength. But to get the best performance from your FRP grating system, proper installation is essential. As a leading FRP grating manufacturer and supplier, we want to ensure your installation goes smoothly and delivers lasting performance.

In this blog post, we’ll walk you through how to install FRP grating step by step, offer tips for success, and explain why sourcing from a reliable FRP grating supplier makes all the difference.

Before beginning the installation process, gather the necessary tools:

FRP grating panels (molded or pultruded)

Measuring tape and chalk line

Cutting tools (circular saw with diamond blade or carbide-tipped blade)

Grinder or file for edge finishing

Fasteners and grating clips (M-clips, C-clips, G-clips, etc.)

Drill or impact driver

Personal protective equipment (gloves, eye protection, mask)

Plan the Layout

Start by measuring the installation area and planning the FRP grating panel layout. Allow for thermal expansion gaps and ensure the support structure spacing meets the load-bearing requirements (typically 18" to 24" centers).

Cut to Fit (If Needed)

If panels require trimming, use a circular saw with a fiberglass-compatible blade. Always cut in a well-ventilated area and wear PPE. Smooth edges with a grinder or file for safety and a clean finish.

Position the Grating Panels

Place the FRP grating panels on the support structure, ensuring they are level and aligned. Avoid dragging panels across abrasive surfaces to prevent fiberglass damage.

Secure with Grating Clips

Use corrosion-resistant fasteners and clips such as M-clips for molded FRP grating or G-clips for attachment to steel. Follow manufacturer-recommended clip spacing to ensure stability.

Check Stability and Alignment

After installation, inspect all panels to ensure alignment and rigidity. Test the load distribution by walking gently across the surface.

Edge Banding and Finishing (Optional)

To enhance safety and appearance, consider applying edge banding or capping any exposed edges.

Wear gloves, eye protection, and a mask to prevent fiberglass dust exposure.

Always secure grating panels before stepping on them.

Make sure the support structure is level and clean.

Use only recommended FRP grating clips and hardware.

Partnering with a trusted FRP grating manufacturer ensures you receive quality materials, custom sizing, and professional support. We provide:

Molded and pultruded FRP grating

Custom cut-to-fit panel solutions

Full technical guidance and installation support

Fast, reliable shipping and service

Proper FRP grating installation ensures the best results in industrial, marine, chemical, or commercial environments. By using the correct tools, techniques, and fasteners—and sourcing from a proven FRP grating supplier—you’ll benefit from a durable, low-maintenance flooring or platform system that lasts for years.

Ready to purchase or install FRP grating? Contact us today to speak with a grating expert, get product recommendations, and request a free quote.